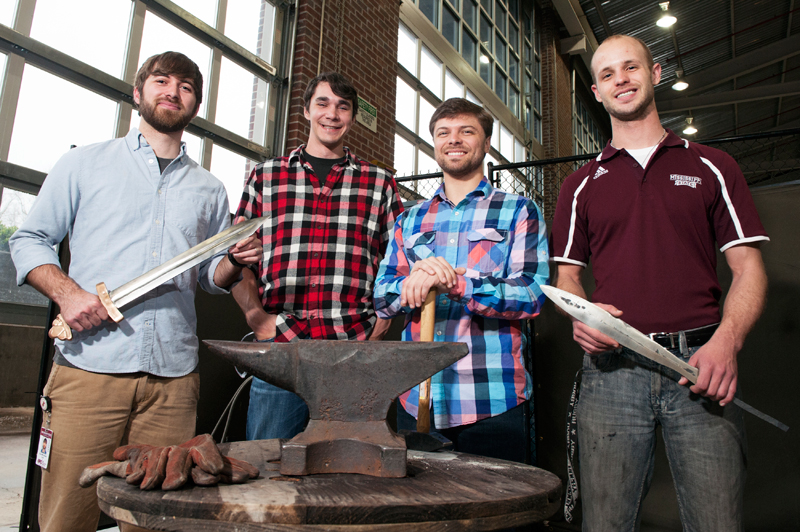

Students test their ‘metal’ in smithing challenge

March 16, 2015

STARKVILLE, Miss. –Bagley College of Engineering students will test their mettle this week when they pit their metal against other universities’ in a national sword-making challenge.

The team of nine students forged, hammered and cast a Viking-style sword for a bladesmithing competition sponsored by the Mineral, Metals and Materials Society in conjunction with its annual conference in Orlando, Florida.

A test of skill and steel, the competition will judge entries on aesthetics, quality of the blade and the team’s knowledge of the metallurgical process.

“This project helped solidify our understanding of the microstructure of steel,” explained mechanical engineering major Zack McClelland, one of the group’s leaders. “We had to learn how heating and cooling can cause it to change and alter the hardness.”

To begin the process, the team built a small forge from an empty munitions box. This allowed them to begin experimenting with the “heat and beat” process of blacksmithing while they finished building a sturdier forge capable of reaching 2,400 degrees Fahrenheit.

The students’ first blade was a test created with low-carbon steel scavenged from leftovers at the Center for Advanced Vehicular Systems, where the team worked. It featured a slightly curved blade in the style of Sting, the sword wielded by Bilbo Baggins in “The Hobbit.”

“We knew it wasn’t the material we ultimately wanted to use, but it was good to practice with in the small forge, “ McClelland explained. “The curves were hard to achieve, but it helped us get a feel for the process of heating and hammering the steel to achieve the desired shape.”

The sword the students will enter into the competition has a blade made of higher carbon steel. It features a broad, tapered style that includes a fuller, or beveled groove, down the center of the blade. The handle consists of a wooden grip, and a pommel and guard cast from bronze. These materials were also salvaged from other projects’ leftovers. The bronze pommel and guard were cast from 3-D printed designs that were used to form a sand and plaster mold.

The students used only a mallet, 8-pound sledgehammer and the muscle it takes to swing them to manipulate the steel into the necessary shape for the blade. The cycle of heating, hammering and cooling made it a slow, tiring process.

The students used only a mallet, 8-pound sledgehammer and the muscle it takes to swing them to manipulate the steel into the necessary shape for the blade. The cycle of heating, hammering and cooling made it a slow, tiring process.

“From class you ‘understand’ the process of hand-hammering steel, but you don’t get a good feel for the difficulty until you’re standing by the fire, swinging the sledgehammer and have the blisters to show for it,” explained mechanical engineering major Jake House.

The students used a high-temperature oven to harden the blade after completing its construction. By rubbing a removable, cement-based coating down the center of the blade before firing, they were able to make the edges harder than the center to ensure that the sword remains ductile and won’t shatter on impact.

The team created its competition sword as part of a directed individual study under the supervision of Judy Schneider, a professor in mechanical engineering and a materials science researcher. Although the sword doesn’t yet have a name, it has been suggested that it be named for their instructor. But the students promise it’s a logical tribute and not just a wishful attempt to secure a better grade—Schneider comes from the German word meaning “to cut.”

The team members include (by hometown):

AMORY – Senior mechanical engineering major Thomas Ritter, son of Robert Ritter

BAY SAINT LOUIS – John Bourgeois, a graduate student in mechanical engineering and the son of John Bourgeois and Kevin Adams

COLUMBUS –Blake Brown, a graduate student in mechanical engineering and the son of Billy and Candi Brown

GUNTOWN – Senior mechanical engineering major Martin Pitts, son of Martin and Marilyn Pitts

KILLEN, Ala. – Zack McClelland, a graduate student in mechanical engineering and son of James and Lenette McClelland

MADISON – Senior mechanical engineering major William Williams, son of Preston and Patricia Williams

OKOLONA – Justin Hughes, a doctoral student in mechanical engineering and son of Robert and Kallie Hughes

PETAL – Robert Layne Smith, a junior majoring in art and son of Jimmy and Darlene Smith.

PERKINSTON – Jake House, a graduate student in mechanical engineering and the son of Allen and Michele House

For more information about the Mineral, Metals and Materials Society’s bladesmithing competition, visit www.tms.org/meetings/annual-15/AM15home.aspx.

Information about the Bagley College of Engineering, including its research in materials science, can be found at www.bagley.msstate.edu.

By Susan Lassetter